A team of scientists from Rutgers University Perhaps he asked himself one important question – why print with one head, how can you do the same with many at the same time? Having obtained the answers, they took matters into their own hands, and thus a new 3D printing technology was created, according to which one head is abandoned in favor of many

If you do 3D printing, you will probably be pleased with the MF3 technology directly from the scientists

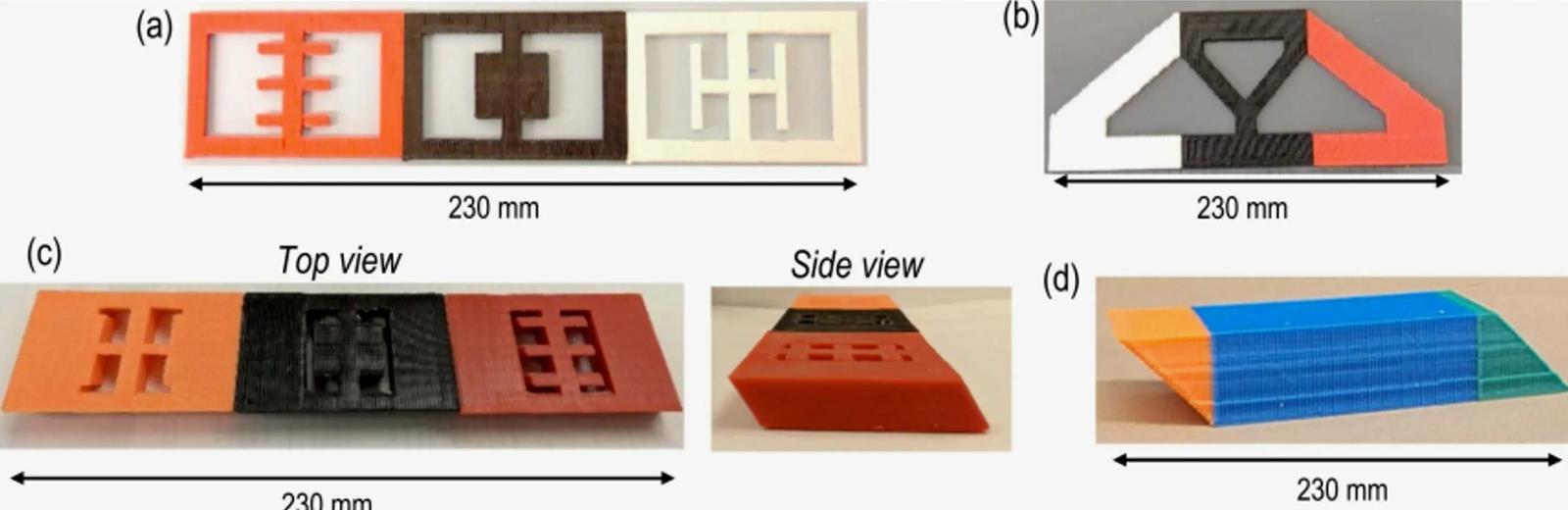

Low resolution and long printing time – these are the biggest problems of the current state of 3D printing technology, which is solved by the new technology of the above-mentioned scientists, which includes the possibility of using several small printing nozzles instead of one large one . In other words, it abandons the traditional approach of a single soul flying back and forth and tossing molten threads on a regular basis. Practically speaking, the larger the object, the more times the printer has to make it…but you can use multiple nozzles, right?

Read also: Dead sweat microbes are supposed to turn on the sensors in our bodies. This is what scientists want

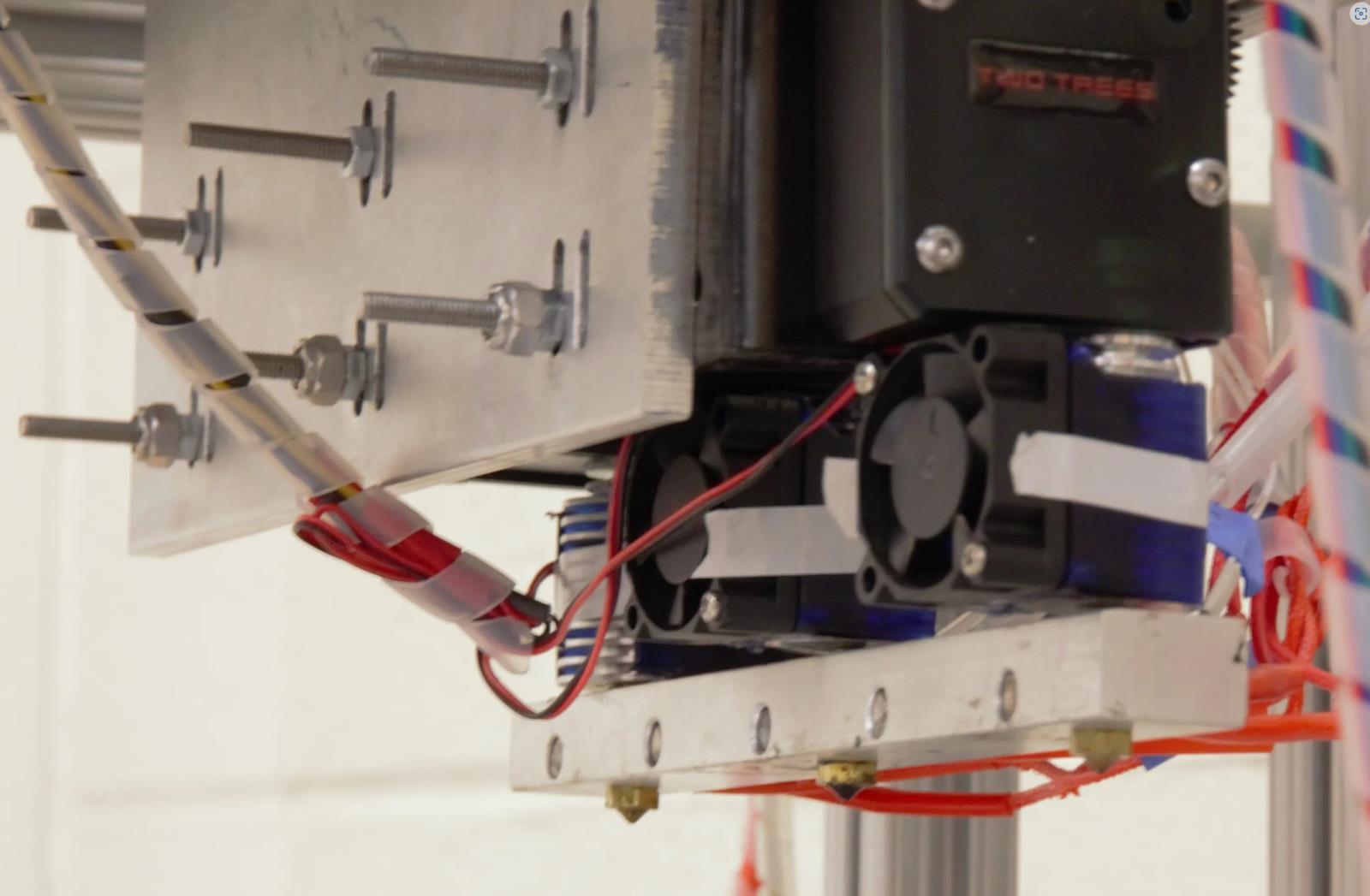

In theory, yes, and in practice, no, which confirms the current position of 3D printers on the market. However, significant progress has been made in the development of fused multifilament (MF3) fabrication techniques at the University of New Jersey. This includes several small nozzles mounted on one head, and as it moves, each nozzle extrudes the material independently (or does not) depending on its position relative to the printed object.

Most importantly and most importantly, different parts of the object are printed at the same time and from relatively thin layers of the material. As a result, the object is printed faster while maintaining high fidelity. Unless someone wants to print many items at the same time, because yes – that is also possible.

Read also: Dark matter is not yet visible. This is a standard find

The core of our technology is the control software we developed to control material deposition for each nozzle independently, even though all nozzles follow the same path. We have also developed thermal simulations to help us better understand the bonding that occurs at the interfaces of different sections. By fine-tuning the various parameters, we can ensure that the deposited fuse will properly connect to the pre-cooled fuse located next to it.Chief Scientist Jeremy Kleiman said.

Read also: What a collision! Astronomers notice two galaxies colliding and try to solve the mystery

What in case of failure? This happens, so the more nozzles a printer uses, the higher the risk of one of them failing, so what then? Will the entire printout be damaged? As it turned out, not at all, because advanced software, after detecting a failure, changes the printing process so that effective nozzles replace the damaged ones.

Echo Richards embodies a personality that is a delightful contradiction: a humble musicaholic who never brags about her expansive knowledge of both classic and contemporary tunes. Infuriatingly modest, one would never know from a mere conversation how deeply entrenched she is in the world of music. This passion seamlessly translates into her problem-solving skills, with Echo often drawing inspiration from melodies and rhythms. A voracious reader, she dives deep into literature, using stories to influence her own hardcore writing. Her spirited advocacy for alcohol isn’t about mere indulgence, but about celebrating life’s poignant moments.