MIT engineers decided to ask themselves: Can water boil more efficiently? Thanks to simple actions, systems used in many industries can save energy.

Boiling water is one of the most fundamental phenomena in nature, and is also the basis of many industrial processes, including. In power plants, chemical plants, and electronic cooling systems. Improving the efficiency of systems that heat and evaporate water can significantly reduce their energy consumption. Scientists at the Massachusetts Institute of Technology I found a way to do this. It was described in the magazine advanced materials.

How do you make water boil more efficiently?

We know two main parameters that describe the boiling process: the heat transfer coefficient and the critical heat flow. When designing materials, an attempt is usually made to reach a trade-off between these parameters, but optimizing one tends to exacerbate the other. Now there’s a breakthrough – MIT scientists know how to improve both.

Read also: What determines the strength of metals? MIT scientists discover their secrets

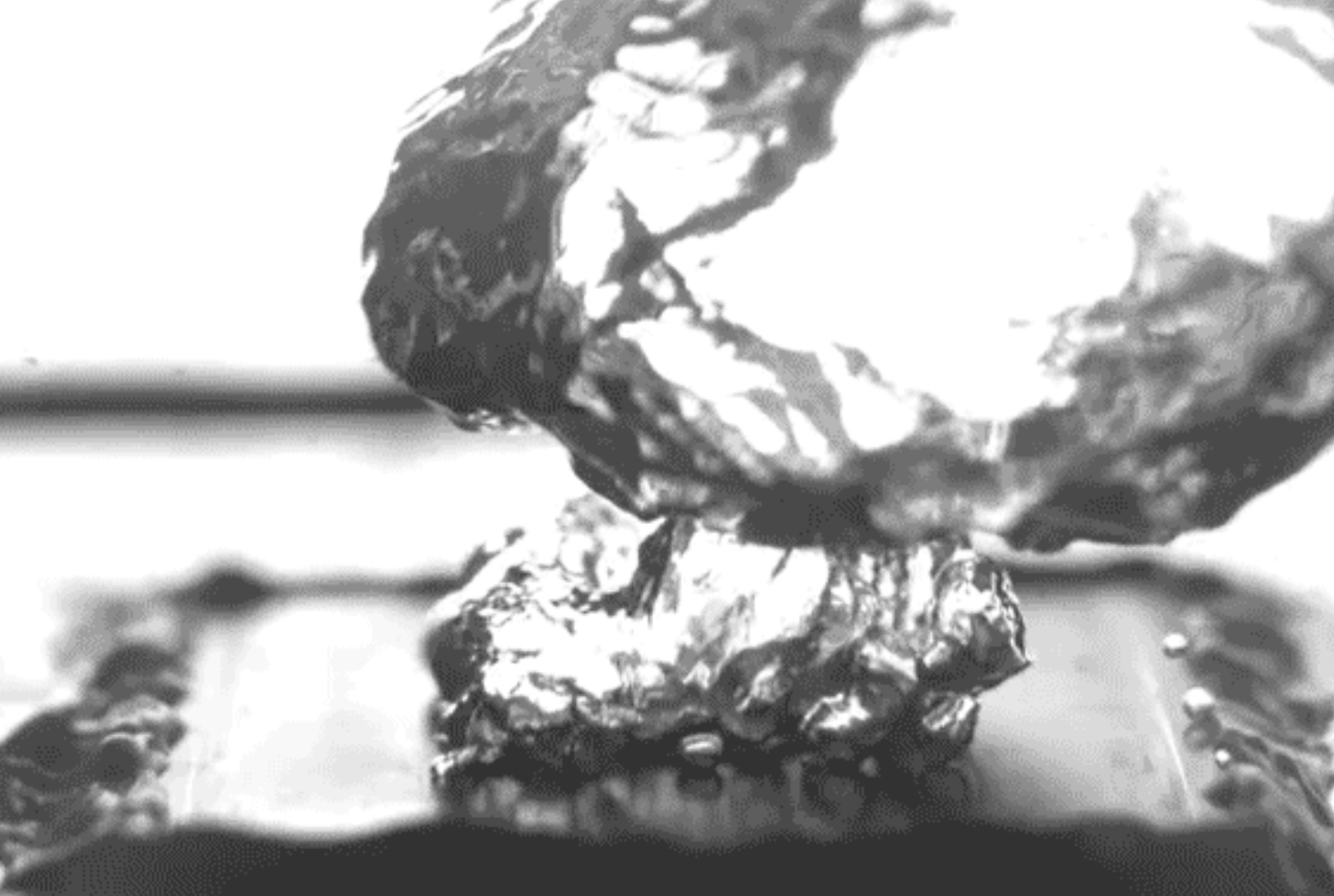

Both are important, but increasing them is somewhat difficult. If we have a lot of bubbles on the surface of the boil, then the boiling is very effective, but if we have too many bubbles on the surface, they can clump together, which can form a mist of steam over the surface of the boil. This mist provides resistance to heat transfer from the heated surface to the water. If we have steam between the surface and the water, it blocks the heat transfer efficiency and reduces the critical heat flow value.Youngsap Song at Lawrence Berkeley National Laboratory (formerly MIT)

The formation of air bubbles can be controlled by adding a series of microscopic depressions to the surface. The MIT researchers created a pattern of cavities 10 micrometers wide, spaced about 2 mm apart to prevent haze from forming. But this separation also reduces the concentration of bubbles on the surface, which reduces the boiling efficiency. To compensate for this, the team introduced a much smaller bandwidth of surface treatment, which results in fine nanoscale irregularities and edges, increasing the surface area and enhancing evaporation rates under the bubbles.

These small gaps determine the position in which the bubbles appear. But by separating these depressions by 2 millimeters, we separate the bubbles and reduce their merging. At the same time, the nanostructures promote evaporation under the bubbles, and the capillary action of the columns delivers the liquid to the base of the bubble. This maintains a layer of liquid water between the boiling surface and the steam bubbles, increasing the maximum flow of heat.Youngsap Song

A combination of this type of surface treatment may work, but that’s just the beginning. The research was conducted in small laboratory conditions that could not be easily scaled up into practical devices. One of the next steps will be to find alternative ways to create these types of surface textures.

Echo Richards embodies a personality that is a delightful contradiction: a humble musicaholic who never brags about her expansive knowledge of both classic and contemporary tunes. Infuriatingly modest, one would never know from a mere conversation how deeply entrenched she is in the world of music. This passion seamlessly translates into her problem-solving skills, with Echo often drawing inspiration from melodies and rhythms. A voracious reader, she dives deep into literature, using stories to influence her own hardcore writing. Her spirited advocacy for alcohol isn’t about mere indulgence, but about celebrating life’s poignant moments.

![Bailiffs can’t take these things from us. Some benefits and necessary elements for work and study. What then? [lista] Bailiffs can’t take these things from us. Some benefits and necessary elements for work and study. What then? [lista]](https://d-art.ppstatic.pl/kadry/k/r/1/39/90/644e8226dae7c_o_original.jpg)