Plant cells are very invasive to research. Freezing of samples or placing them under vacuum often leads to permanent damage. Now a team of American physicists have used the latest version of optical microscopy to study the formation of poplar cell walls without damaging the specimens.

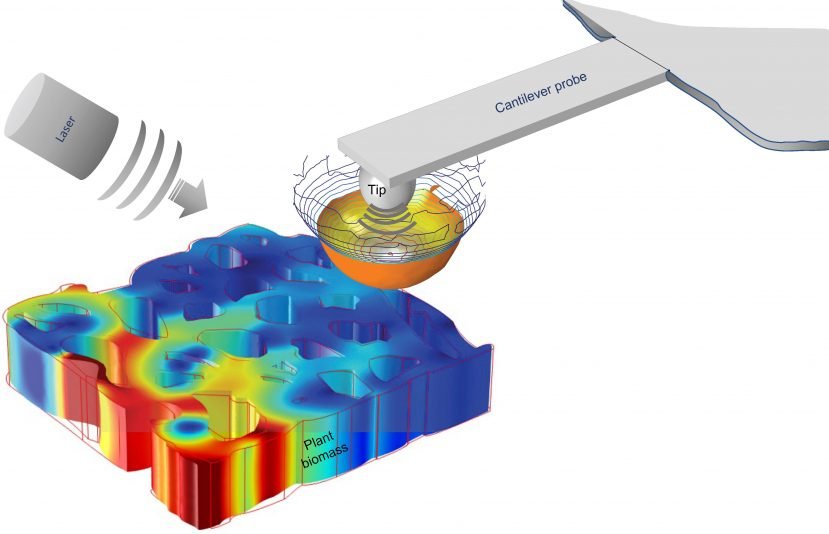

A team of scientists from Oak Ridge National Laboratory Led by Ali Bassian, he developed a new technique for observing cell nanostructures. Although plant cell walls are difficult to study due to the presence of complex polymers such as microfibers, scientists have come up with a resolution of more than 20 nanometers, which is about 1,000 times smaller than a strand of human hair. Details are described in Communication materials.

Our technology allowed us to take a look at the sample’s shape and its optical and chemical properties at the nanometer scale – all in one measurement.Ali Bassian

Also participating in the study were researchers from Aix-Marseille University, the Interdisciplinary Center for Nanoscience in Marseille, the Fresnel Institute and the company Neaspec.

To date, these optical properties have not been measured in situ, but only on the basis of isolated components that do not provide information in terms of compositional and chemical properties.Aud Lerio from the Fresnel Institute

Using a measurement technique to obtain a series of detailed images in a single area of the poplar wood cell wall, the researchers observed the distribution of structural polymers such as lignin and cellulose, solids that serve as “bones” for biological systems and can be extracted into biofuels and bioproducts. The data collected can be used to improve chemical processing methods that use acids or enzymes to increase the productivity of polymers and prevent degradation of biomaterials due to external factors.

When changing a substance, it is important to carefully monitor the changes at the molecular level. By applying our technology to a pre-treated poplar sample, we were able to examine the sample while tracking any changes that might affect its viability.Ali Bassian

The newly developed method may be important in the fields of 3D printing technology. During the printing process that Bassian describes as a more complex version of applying icing to a cake with a baking tray, the metering technology can provide an extra layer of quality control to reduce human error, correct material placement and remove any contamination in real time.

Echo Richards embodies a personality that is a delightful contradiction: a humble musicaholic who never brags about her expansive knowledge of both classic and contemporary tunes. Infuriatingly modest, one would never know from a mere conversation how deeply entrenched she is in the world of music. This passion seamlessly translates into her problem-solving skills, with Echo often drawing inspiration from melodies and rhythms. A voracious reader, she dives deep into literature, using stories to influence her own hardcore writing. Her spirited advocacy for alcohol isn’t about mere indulgence, but about celebrating life’s poignant moments.