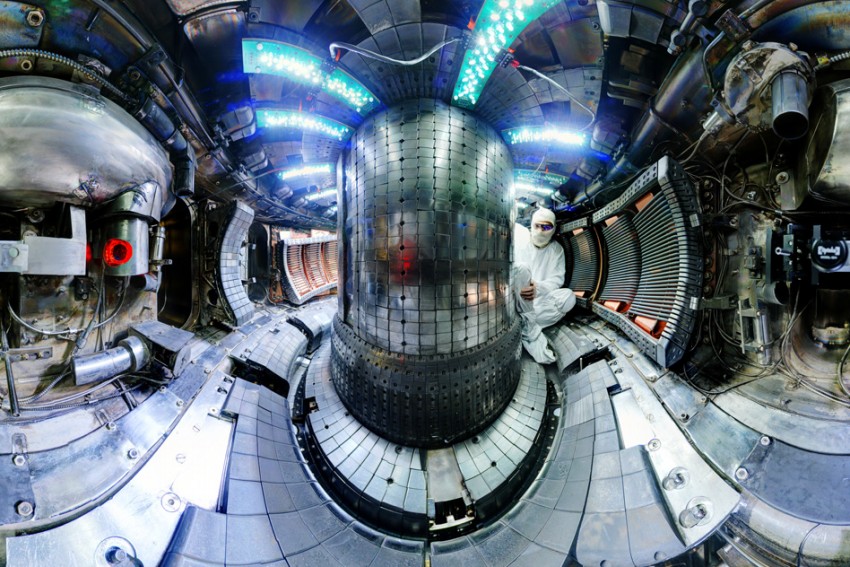

A new coating was created at the University of Wisconsin-Madison Better protects the walls of the fusion reactor. It could allow the construction of smaller, more efficient reactors that are easier to repair and maintain. We need new manufacturing techniques that allow us to produce fusion reactor components in a cost-effective manner. Our technology represents a significant advance over previously used solutionssays Mykola Jalovija, lead author research.

Scientists used cold spray technology to coat tantalum on stainless steel. Tests of the new coating, which were exposed to conditions similar to those found in nuclear fusion reactors, went very well. The new material turns out to be excellent at trapping hydrogen molecules, which is important in compact fusion reactors. We have found that spray-applied tantalum absorbs significantly more hydrogen than tantalum applied using standard techniques. It has a unique microstructure“, explains Professor Kumar Sreedharan. Over the past decade, Sreedharan’s research group has developed the cold deposition technology for the nuclear industry, and it is now finding many applications. An additional advantage of this technology is its simplicity.

In fusion reactors, plasma made of ionized hydrogen is heated to extremely high temperatures, where hydrogen atoms collide with each other and combine to produce energy. However, some of the hydrogen ions lose their charge, become an electrically neutral atom and escape from the plasma. These neutral hydrogen atoms cause energy to be lost from the plasma, making it difficult to keep the plasma hot, which is a particularly serious challenge for small reactors.Yalovija explains.

Tantalum absorbs hydrogen well, and scientists began to suspect that cold spraying might improve its properties further. During spraying, tantalum particles are accelerated to supersonic speeds. When they hit the surface, they flatten and cover the entire surface, but nanometer gaps remain between these flat particles, and as scientists discovered, hydrogen is trapped in them.

Jalovija conducted experiments on the new coating at the University of Aix-Marseille in France and Forschungszentrum Jülich GmbH in Germany. They showed that when heated to a higher temperature, hydrogen atoms trapped in the tantalum shell are released, but the shell itself is not modified. Another advantage of the new coating is that we can repair the reactor on site by applying a new protective layer. Currently, if they are damaged, it is necessary to remove the damaged parts and install new ones, which is expensive and time-consuming.Yalovija explains.

The high-temperature coating, which allows for good hydrogen capture and is highly durable and corrosion-resistant, is a breakthrough in fusion systems. Particularly interesting is the possibility of changing its composition and introducing other resistant mineralssummarizes Professor Oliver Schmitz, whose laboratory Yalovija works in.

The new coating will be used on the Wisconsin HTS Aximetric Mirror (WHAM) currently under construction. This experimental device will be a prototype for future next-generation reactors. It was created thanks to a collaboration between the University of Wisconsin-Madison, the Massachusetts Institute of Technology (MIT) and Commonwealth Fusion Systems.

Echo Richards embodies a personality that is a delightful contradiction: a humble musicaholic who never brags about her expansive knowledge of both classic and contemporary tunes. Infuriatingly modest, one would never know from a mere conversation how deeply entrenched she is in the world of music. This passion seamlessly translates into her problem-solving skills, with Echo often drawing inspiration from melodies and rhythms. A voracious reader, she dives deep into literature, using stories to influence her own hardcore writing. Her spirited advocacy for alcohol isn’t about mere indulgence, but about celebrating life’s poignant moments.

![Full Collection of Popular Movie Slot Games [July 2022] Full Collection of Popular Movie Slot Games [July 2022]](https://www.moviesonline.ca/wp-content/uploads/2024/09/Picture1-260x140.png)